Services

Site Services

The range of site services provided by Perrott Engineering is extensive; basically anything involving hydraulics, pneumatics, lubrication or greasing systems. The following summaries give some indication of the depth of knowledge and experience available to assist you in the operation of your business.

Audit and Advisory Service

Due to our many years of experience in a wide variety of industries, we are able to offer a comprehensive Site Audit Reporting and Advisory service in relation to any hydraulic or lube system problems. This service is often utilised to uncover the root cause of reoccurring and consistent problems or plant failure that have proven difficult to solve. These audits can cover just one specific section of plant or the entire range of hydraulic systems including filtration problems, overheating and cooling, moisture and contaminant ingress, preventative maintenance planning, recommended servicing levels and periods, spare parts holdings etc.

If you would like to see the depth and content of a sample site audit report, or wish to discuss a site audit for your site, please contact our Engineering Department at engineering@perreng.com.au

This site auditing then often leads into corrective action and we have a number of site experienced technicians who regularly travel and work at customer sites to implement the corrective actions and upgrade recommendations made in the Audit Report. These tradesmen come equipped with a 6 meter site container fitted out with all the tooling, welding, hose making and tube bending equipment required for the job.

We have a number of these site containers and often have three or four such units scattered around Australia and PNG for up to 12 months at a time.

On Site Servicing and Installation

Our service personnel have extensive experience in marine, mining, oil and gas and industrial site work.

We maintain full records on all service personnel’s training, passports, foreign work visas, Police checks, etc. and usually have a number of suitably qualified and documented service technicians available at short notice to attend any emergency breakdown or service work.

With regular daily flights out of Cairns to Port Moresby in PNG and Asia as well as to all Australian capital cities, we are able to deploy service personnel quickly and efficiently.

Our northern location in the Australian continent gives us a competitive edge in servicing all of Northern Australia as well as our neighbouring countries, and our Cairns service centre is the largest and best equipped facility of this type in the region.

We have service personnel at Australian and overseas mine sites, power generation sites, offshore oil platforms and overseas shipyards on a regular basis.

If you have a need for site services, please use the link to contact our Service Manager: service@perreng.com.au

Oil Condition Monitoring and Diagnostic Testing

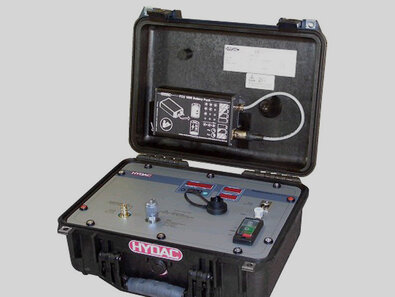

Perrott Engineering utilise a number of portable particle counting units for use in testing and monitoring hydraulic and lube oil system cleanliness levels. These units are able to carry out live contamination particle counting in all oils and heavy fuels up to 350cst viscosity and the results are available in minutes.

These particle contamination counter units are calibrated annually by the manufacturer to ISO Standards to ensure ongoing accuracy.

Our workshop and service vehicles are fitted with a full range of analogue and digital portable hydraulic testing equipment for flow, pressure, temperature and speed. We also utilise a number of electronic data loggers that can record a systems operating parameters over time and these tools allow us to diagnose any hydraulic system malfunction. These digital units will record system operating pressure at up to 1000 times a second, so are useful in detecting short pressure spikes in systems that can cause equipment malfunction or failure.

If you would like to discuss oil condition monitoring for your plant, please contact our service manager on the following link: service@perreng.com.au

Fluid Transfer, Flushing and Filtering

Our Cairns service centre has a range of portable flushing and filtering units for onsite fluid transfer and system flushing. Some of these units have variable speed drives to give an output flow to suit the system and achieve the required turbulent flow to give fully controlled flushing and filtration of any circuit.

Two or more units can also be combined to give the necessary flows on larger systems. We also utilise a temperature controlled 1000 litre stainless steel reservoir to provide flushing medium storage when necessary and fluid heating to achieve the required Reynolds Number turbulent flows required for successful flushing.

These units used in conjunction with the portable Particle Counters can be used to flush and continuously monitor any hydraulic system or diesel fuel transfer and filtering application.

We have extensive experience flushing hydraulic and lubrication pipework and complete systems in the marine, power generation, mining and oil and gas industries to meet any applicable standard, and this cleaning and flushing can be done in our Cairns service centre if practical or onsite at your plant.

If you would like to discuss your fluid transfer, flushing or filtering requirements for your site, please contact our service manager on the following link: service@perreng.com.au