Hydraulics & Lubrication

Design

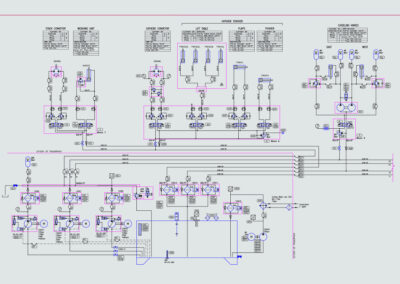

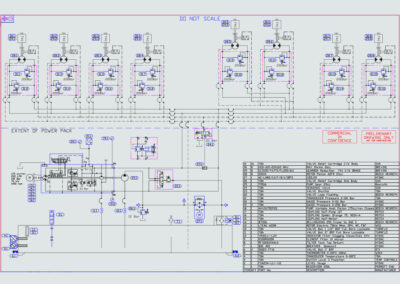

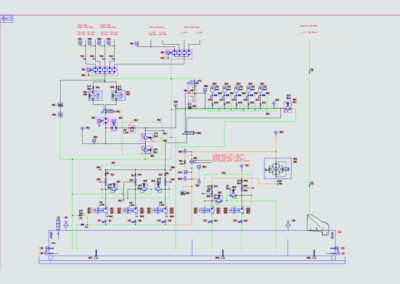

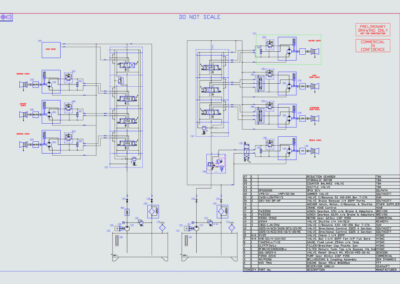

Hydraulic System Design and Drafting Service

Our team of tertiary qualified Mechanical Engineers use a number of CAD programmes including Solidworks and AutoCAD to carry out all design and drafting work. We also utilise FEA software to verify all design work as necessary.

Systems and individual components can be designed to comply with any relevant standards or Class Society Rules. The list below shows some of the more common Standards and Class Society Rules we regularly work within.

- All AS/NZ Standards

- BV (Bureau Veritas)

- ISO Standards

- DNV (Det Norske Veritas as.)

- DIN Standards

- API (American Petroleum Institute)

- Lloyd’s Register

- ABS (American Bureau of Shipping)

Examples of previous project completed by our design team include the following.

Winches

Perrott Engineering can custom design and manufacture a winch of practically any size and operating parameters to suit your specific application. Our engineering team will work with you to meet all your requirements regarding safety features, maximum line pull, and drum capacity, braking etc. for the application.

16 Tonne line pull winch with grooved drum, DNV approved

16 Tonne line pull winch with grooved drum, DNV approved

Special application winch with integrated diesel HPU and grooved drum

Special application winch with integrated diesel HPU and grooved drum

5 Tonne DNV approved winch with Archimedes screw style level wind

5 Tonne DNV approved winch with Archimedes screw style level wind

Dual drum winch, 12T/5T line pull, DNV approved and hydraulic pendant controls

Dual drum winch, 12T/5T line pull, DNV approved and hydraulic pendant controls

Hydraulic Power Units

Perrott Engineering can custom design and build a hydraulic powerpack of any size and power input type to suit your specific application, from 0.5 kW to 500 kW. Electric, single or three phase, diesel or air powered. The photos below depict just some of the different types of powerpacks we have designed and manufactured over the years.

132kW Diesel HPU to drive 3 winches in closed loop, and 2 cylinders in open loop circuits

132kW Diesel HPU to drive 3 winches in closed loop, and 2 cylinders in open loop circuits

37kW Luff and Slew HPU For a materials handling machine

37kW Luff and Slew HPU For a materials handling machine

37kW Luff and Slew HPU For a materials handling machine

37kW Luff and Slew HPU For a materials handling machine

Mill and Gearbox Lubrication Systems

Perrott Engineering can custom design and build a lubrication system to suit your specific application. We have built lubrication systems to suit everything from simple gearboxes to complex ball and sag mill applications in the mining industry.

Our designers are experienced in field layouts and you will find our lube systems are very easy to service and effect component changeouts when necessary. Our systems are designed and built with the functionality and serviceability foremost in mind, and while this may sometimes result in a slight capital cost increase, this will be saved many times over during the life of the lube system.

Mill down time is expensive and every hour saved in doing a pump or filter element changeout is important.

The ready availability of replacement components such as the pumps is also important, so we specialise on utilising readily available components that can be obtained quickly and at a reasonable cost within Australia.

We have built systems that are air to oil cooled, water to oil cooled and chilled water to oil cooled, so we have the experience to meet your expectations and site requirements.

Complete SAG mill lube system change out with duty and standby arrangements

Complete SAG mill lube system change out with duty and standby arrangements

Complete mill lube system change out, tank top style with complete redundancy

Complete mill lube system change out, tank top style with complete redundancy

Mill lube system upgrade, flow divider panel with easy to read flow meters and pressures

Mill lube system upgrade, flow divider panel with easy to read flow meters and pressures

Custom Hydraulic Applications

Perrott Engineering can custom design and build a lubrication system to suit your specific application. We have built lubrication systems to suit everything from simple gearboxes to complex ball and sag mill applications in the mining industry.

Our designers are experienced in field layouts and you will find our lube systems are very easy to service and effect component changeouts when necessary. Our systems are designed and built with the functionality and serviceability foremost in mind, and while this may sometimes result in a slight capital cost increase, this will be saved many times over during the life of the lube system.

Mill down time is expensive and every hour saved in doing a pump or filter element changeout is important.

The ready availability of replacement components such as the pumps is also important, so we specialise on utilising readily available components that can be obtained quickly and at a reasonable cost within Australia.

We have built systems that are air to oil cooled, water to oil cooled and chilled water to oil cooled, so we have the experience to meet your expectations and site requirements.

Cylinders

Perrott Engineering can custom design and build hydraulic cylinders and replacement components to suit your specific application. We have built many custom hydraulic cylinders to suit our client’s needs in applications from marine steering systems, to drilling rigs for the oil and gas industry, to cranes for shipyards. We can manufacture with special materials such as stainless steels to suit arduous operating environments or incorporate special valving into the cylinder design.

Hydraulic Service Equipment

Some of the specialist hydraulic servicing equipment that Perrott Engineering has manufactured for clients in the past are such items as cylinder pull down benches of varying sizes and lengths, pump and motor test benches and honing machines.

The cylinder pull down benches and honing machine shown in this publication were all designed and manufactured in house by Perrott Engineering and have been designed based on the experience and knowledge gained in our 45 years in general engineering and 30 plus years specialising in hydraulic servicing.

We don’t just design and manufacture this equipment, we use it in our service centre every day and as a result, we know what works best and does the job in the most economical time and manner. We also build for quality and this will cost more in the initial purchase, but this extra capital cost is repaid many times over with reliability, functionality and backup service.

Custom 6m long cylinder pulldown bench, full hydraulic operation with joystick controlled operations

Custom 6m long cylinder pulldown bench, full hydraulic operation with joystick controlled operations

Custom 6m long cylinder pulldown bench, with fully integrated hydraulic power unit under bench

Custom 6m long cylinder pulldown bench, with fully integrated hydraulic power unit under bench

14m Pulldown bench manufactured for a client overseas, was able to be split to fit into a 40 foot container for shipping purposes

14m Pulldown bench manufactured for a client overseas, was able to be split to fit into a 40 foot container for shipping purposes

Custom manufactured 6m stroke horizontal honing machine with capability of honing up to 500mm diameter bores. This machine is installed in our Cairns Service Centre

Custom manufactured 6m stroke horizontal honing machine with capability of honing up to 500mm diameter bores. This machine is installed in our Cairns Service Centre

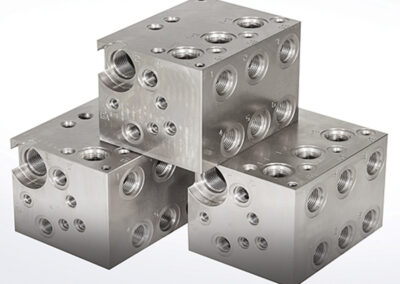

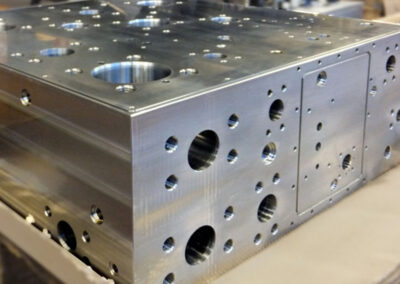

Manifolds

Manifolds are used in hydraulic and lubrication systems to reduce the number of hoses, pipes and fittings used in a circuit to achieve the required system functions. They reduce the physical area and volume the system would occupy and generally make an installation neater, tidier and more compact.

If not designed correctly, they can be a serviceman’s nightmare, with no way of testing and setting the various valves incorporated into the manifold due to the poor design. This usually results in service personnel having to replace valves cartridges one by one until the problem goes away. Not the best solution.

As Perrott Engineering is basically a service oriented business, owned and staffed by tradesmen with considerable experience in the hydraulic service industry, we understand how to design a manifold and incorporate all the necessary test and set features into the manifold.

This may add a little complexity and small cost increase into the original build, but it will recover that cost many times over during the life of the unit, simply due to the fact that the service personnel can quickly and easily test and set each component valve of the manifold in situ without having to second guess anything.

Our Mechanical engineers use the latest CAD programmes to design all our manifolds and verify design strength with the FEA software. We design to suit the system need, not to be the smallest, cheapest or look the prettiest. Our manifolds are functional and serviceman friendly, as we believe that in the long term, they are the primary considerations in manifold design.

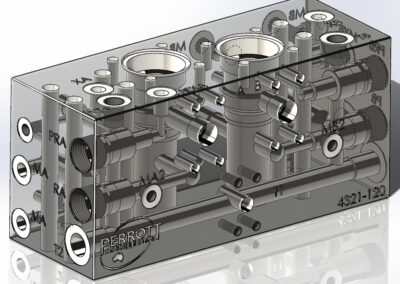

Custom manifold during design phase in 3D CAD software with internals shown

Custom manifold during design phase in 3D CAD software with internals shown

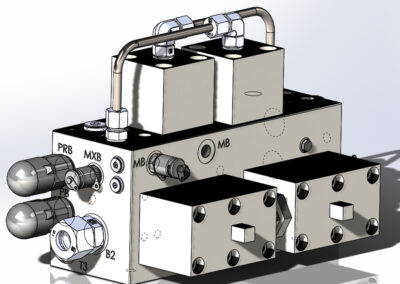

Custom manifold during design phase in 3D CAD software as an assembly with components added for interference checking

Custom manifold during design phase in 3D CAD software as an assembly with components added for interference checking

Mill Inching Drives

Over the last 20 or more years we have been asked to supply new as well as redesign old inching drives on mills of all types and sizes.

This has resulted in our gaining considerable experience with these particular type of drives and the unique problems they experience.

We have provided both electric and closed loop hydraulic drives and in most situations, we find the hydraulic drives are more suited to this application.

We are able to carry out a full analysis of you system if it is experiencing operational issues and provide you with a comprehensive report and proposal on its repair, upgrade or replacement.

The drives we design provide very fine control of the mill inching and include any and all safety features and interlocks you may require to meet your site conditions.

Custom designed and built dog clutch and coupling for inching drive

Custom designed and built dog clutch and coupling for inching drive

Custom built inching drive with quick connect connections, manufactured to be relocated from one mill to another as required

Custom built inching drive with quick connect connections, manufactured to be relocated from one mill to another as required

Special and Obsolete Components

We are often called upon to manufacture parts for customers that are not readily available, have long lead times from the OEM, or are simply priced by the OEM at a cost that is hard to justify. We have the experience, skilled machinists and equipment to manufacture almost anything in this field.

Our Bruker Portable XRF Analyser allows us to determine the composition of all metallic materials in a matter of minutes, our Mitutoyo Hardness tester allows us to determine material hardness, and with this knowledge we can be sure we have selected the correct material to manufacture your item from.

Reverse engineering is something we are getting more call for on a regular basis as equipment owners are looking to keep their plant operating longer and in a rapid changing world OEM parts are often becoming more difficult or impossible to source.

Reverse engineered valve actuators

Reverse engineered valve actuators. These valve actuators were no longer available from the OEM and very tight special requirements meant that there was not a suitable replacement available in the market, so we manufactured replacements keeping the existing outside dimensions