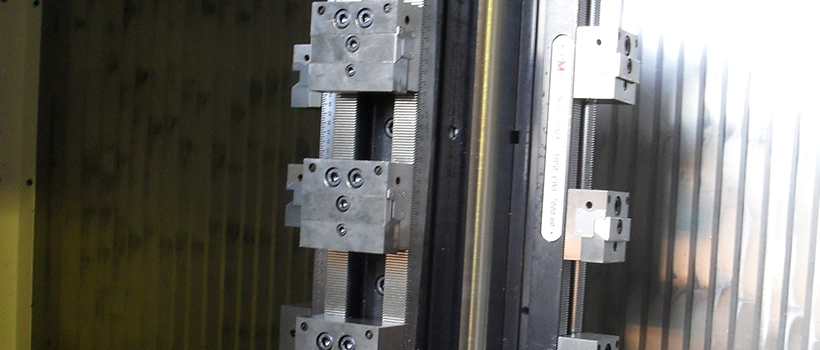

In the last quarter of 2018, we invested in excess of $30,000 in additional special tooling and job holding jigs for our Mazak VTC 800-30SR Vertical Machining Centre. This machine is a 5 axis machine with a 3m bed and the power to handle any manifold job in any material.

We specialise in the fast delivery of one off/special manifolds in all materials including stainless steel, but now have the tooling and jigs to hold and machine multiple units in the one setup and so have become very competitive with our pricing.

We have all solid carbide tooling for all the common cavities to suit Sun, Comatrol, Hydraforce, etc. cartridges, BSPP, NPT, UNO cavity tooling as well as the special boring tools and internal threading tools to machine the uncommon or special cavities.

We can help with the design or drawing of your job and we are not limited to just manifolds. The photos in this site show some of the different items manufactured on this machine in recent times.

Manifolds that we design are tested in our hydraulic test room to their designed test pressure and their designed operation is verified. Inspection and test sheets, where necessary, are supplied with every batch lot manufactured.

We hold considerable stocks of 6061-T6 aluminium bar in stock as well as K1045 carbon steel, so job turnaround time is held to a minimum and special rush orders can be accommodated.