Mechanical Components Of All Types

Air Intake Trumpets

These different length air intakes were manufactured for a racing car enthusiast.

Each different length produces slightly different performance from the engine so the only way to achieve your best results is to try the different length trumpets.

Bellhousing Adaptor Plate

These plates were designed and manufactured to allow a different engine to be installed into a 4WD vehicle utilising the original bellhousing and gearbox. We carried out detailed measurements on the rear mounting area of the new engine and the old bellhousing and combined the two in the CAD programme to produce a design for the adaptor. Machined from 35mm solid steel plate, we have now made numerous of these adaptors and they are in use all around Australia.

Complex and Uncommon Threads

In addition to all the common machine threads, we have the capability to manufacture/reverse engineer any complex or uncommon thread types such as these double start square threads used in valve stems. Other uncommon threads we have machined include API, Buttress, ACME, Knuckle, and tapered buttress. These threads are used in such areas as lead and feed screws in lathes, mills and other machine tools, underground boring and drilling equipment etc.

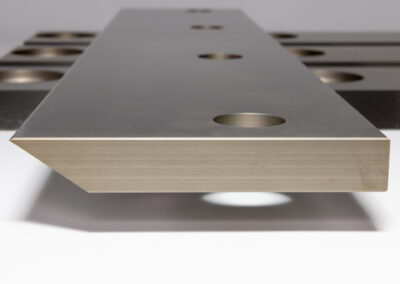

Cutters and Blades

We have the capability to design and manufacture cutter blades of any type within the machining capabilities of our surface grinders.

The blades shown below are used on a waste plastic chopper to reduce plastic offcuts from moulding machines into reusable pellets. They are made from D2 Tool steel plate, machined, ground, hardened and then finish ground all over after hardening on the four long faces to give a precision blade that can be adjusted very tight on the anvil and provide long service life. They can also be reground as needed but must be done as a set. These blades also have a secondary back grind on the cutting edge.

Gearbox Housing

On this occasion our customer was in trouble as the original gearbox manufacturer was no longer in business and his housing was irreparably cracked and damaged.

We reverse engineered the old housing and machined this new steel unit up in a matter of hours using the MasterCam programme installed in our Mazak Vertical Machining Centre.

Pump Shafts

One of our mining customers was experiencing very short life span with some pump shafts in a corrosive environment. We upgraded the specifications of the material used in the shafts to a special duplex stainless steel and shaft life has now returned to an acceptable level. This same upgrading can be applied to almost any component where you are having trouble getting a better product from your OEM or, in most cases, the OEM simply doesn’t manufacture from the best material for your application and you are expected to accept less than desirable performance.